VETERAN OWNED AND OPERATED

Systems we offer

Standard

- Complete removal of existing coatings

- Patching all cracks and holes

- Grinding substrate with machines equipped with diamond tooling all attached with HEPA fitted dust collectors to create a surface profile to concrete that will promote maximum adhesion for coating.

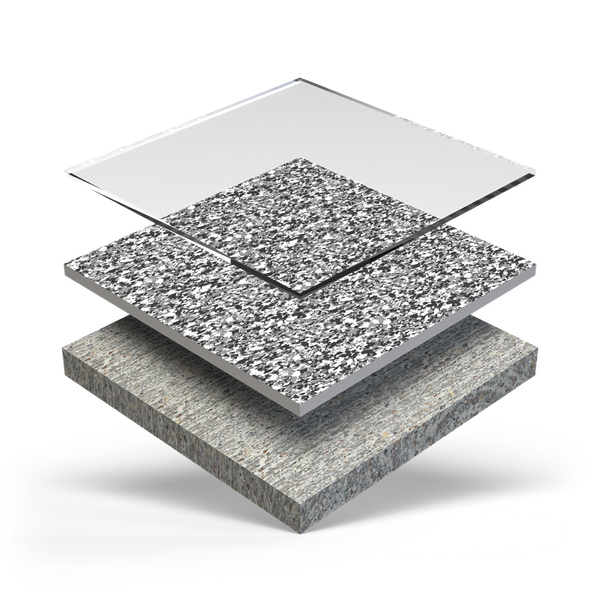

- Base layer of pigmented moisture tolerant Epoxy with Flake broadcasted until full rejection.

- Top coat of UV stable Polyaspartic with traction enhancing agent.

Premium

- Complete removal of existing coatings.

- Patching all cracks and holes

- Grinding substrate with machines equipped with diamond tooling all attached with HEPA fitted dust collectors to create a surface profile to concrete that will promote maximum adhesion for coating.

- Base layer of moisture tolerant Epoxy.

- UV stable pigmented Polyaspartic with Flake broadcasted until full rejection.

- Top coat of UV stable Polyaspartic with traction enhancing agent.

Cracks and depressions

Patching

Unsightly cracks in your concrete is completely normal. Concrete moves due to temperature changes and the soil beneath settling. Before we coat your floor, we chase cracks with a cutting wheel attached to a hand grinder, clean them out, and then fill them with either, thickened epoxy or urethane materials. Once these materials harden we grind them flush. One thing to know about crack patching is that there is a chance your concrete continues to move causing the patches and coatings to crack as well. Any holes or depressions we come across on your slab we grind out, clean, and patch with the same materials used for cracks.

Hand troweled cove base

Thick and extremely durable

Hand troweled cove base typically is used in industrial spaces, hospitals, commercial restrooms and laboratories. The cove seals the edges of your room allowing for ease of clean up due to the fact that dirt and contaminants wont get wedged under base boards and into seams. Hand troweled cove base is much thicker and more durable than our standard ”paint on” cove.

Hand mixed and crafted

As depicted above, Mike is using a hand trowel to put our cove material on the wall, he then comes behind with a cove trowel to form the base. The products bond to the wall and the floor creating a seamless transition. Once applied and cured, we then proceed with resin and flake to match the system chosen by you.

standard cove base

Easy to clean and durable

Typically used in residential settings. This cove base is durable but not meant to take heavy traffic and abuse such as in an industrial setting.The typical home owner‘s garage that is used to store belongings, a golf cart, or a vehicle would be a great application for this. The cove makes a seamless transition from the wall to the floor making it very easy to clean. Dirt, grime, and contaminants wont get wedged under base boards or into the seam that most garages have where the floor meets the wall.

The process

We thicken our epoxy materials and hand trowel just enough material to fill the seam that exists from the floor to the wall. This creates a “ramp” like feature as well as creates a seamless transition from the wall to the floor. Once applied and cured we continue with resin and flake to match the system chosen by you.

joint fill

Honoring the control joint

When honoring control joints (which is recommended) we open them up a bit more and round down the edges to allow our products a better place to bond. This also gives your joints a more consistent look as well as making them easier to clean out if dirt collects inside.

Filling the control joint

Concrete moves over time for various reasons such as temperature changes and the ground beneath it settling. This results in cracking. Control joints are cut into slabs to promote cracking within the cuts. If we fill them to create a seamless floor, there is a high probability of cracking on our coating along the filled cuts. However, we do offer this service and it looks amazing!

epoxy vs polyaspartic

EPOXY

POLYASPARTIC

POLYASPARTIC

- Excellent base coat.

- Can be formulated to withstand hydrostatic pressure emitting from concrete substrates. This is why we always use epoxy as the first layer of our systems. Some companies will use Polyaspartic as a base coat, this is a huge mistake, poly’s do not handle moisture vapor transmission at all and WILL delaminate eventually If

- Excellent base coat.

- Can be formulated to withstand hydrostatic pressure emitting from concrete substrates. This is why we always use epoxy as the first layer of our systems. Some companies will use Polyaspartic as a base coat, this is a huge mistake, poly’s do not handle moisture vapor transmission at all and WILL delaminate eventually If used directly to substrate. Companies will use Polyaspartic as a base coat to save time due to their fast curing nature. Please do not fall into that trap.

- IS NOT UV STABLE no matter what anyone tells you. Trust us, we’ve learned the hard way. Epoxy WILL amber if exposed to sunlight, there is no way around this at the moment.

- We will never use epoxy as a top coat.

POLYASPARTIC

POLYASPARTIC

POLYASPARTIC

- Polyaspartic is an excellent product for use as a mid coat and a top coat due to its UV stability.

- Great resistance to chemicals including but not limited to, brake fluid, gasoline, motor oil, transmission fluid, and bleach.

- Non-porous so dirt and contaminants will sit on top until easily cleaned off.

- Less rigid than epoxy, therefore making

- Polyaspartic is an excellent product for use as a mid coat and a top coat due to its UV stability.

- Great resistance to chemicals including but not limited to, brake fluid, gasoline, motor oil, transmission fluid, and bleach.

- Non-porous so dirt and contaminants will sit on top until easily cleaned off.

- Less rigid than epoxy, therefore making them withstand more use and abuse.

- We use Polyaspartic as a mid coat when UV stability is a must, such as, the use of light colors or when used outdoors.

- All of our floors get Polyaspartic as a top coat with traction enhancement, either mixed in, or broadcasted on top.

Our Partners